FENIX NTM Blu Fes Modern Style Plywood Core Kitchen

Fully bespoke kitchen manufactured to exact room dimensions | FENIX NTM matte fronts | Plywood-core construction

Project Overview

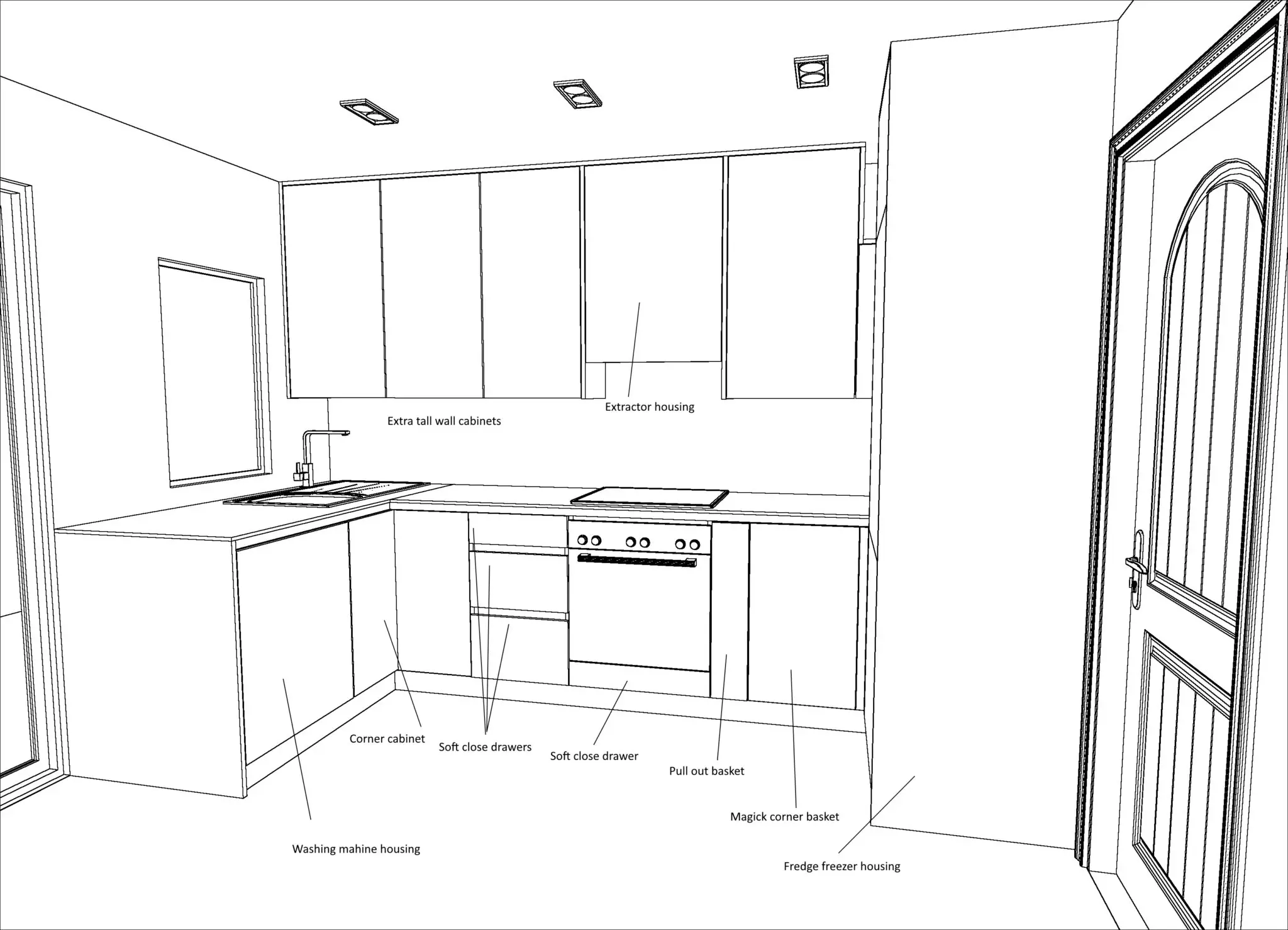

This project features a modern L-shaped kitchen finished in FENIX NTM Blu Fes, built using a plywood-core cabinet structure and manufactured specifically for the proportions of the room. The objective was to create a calm, contemporary space with strong daily usability, precise alignment, and long-term structural stability.

Rather than adapting standard module sizes, the cabinetry was produced from scratch to suit the existing room layout, including the tall cabinet run positioned beside the glazed door and the continuous base units forming the main preparation and cooking zone.

Project Overview

The layout follows a compact but highly functional L-shape configuration, allowing for uninterrupted worktop space and a logical flow between preparation, cooking, and cleaning areas. Wall units were positioned to maximise vertical storage without visually compressing the room, while a tall cabinet block consolidates height into one controlled architectural element.

This approach reflects how we structure bespoke kitchen manufacturing — proportions are determined by the room itself, not by fixed factory module increments. Even in smaller kitchens, careful control of door splits, vertical lines, and panel alignment significantly influences how refined the finished result feels.

Materials and Construction Specification

The cabinetry is constructed using a plywood-based core system, selected for its dimensional stability and long-term rigidity. The fronts are finished in FENIX NTM Blu Fes, a deep matte blue surface known for its low reflectivity and smooth tactile quality.

- Plywood-core cabinet construction for structural integrity

- FENIX NTM Blu Fes matte laminate fronts

- Light-toned worktop for visual contrast

- Warm neutral splashback to soften the deep blue palette

- Under-cabinet integrated LED task lighting

The material combination allows the kitchen to maintain a strong modern identity while remaining balanced and comfortable in everyday use. You can explore more about this material system in our overview of FENIX laminate kitchen furniture and how it integrates with precision-built cabinet structures.

Storage and Functional Planning

Even within a relatively compact footprint, storage efficiency was a priority. Base cabinetry along the L-shaped run provides continuous internal volume for cookware and daily-use items, while wall cabinets ensure that worktop areas remain clear and usable.

Appliance positioning was planned to maintain a natural workflow, with the cooking zone integrated cleanly into the main run. Rather than relying on default internal layouts, the configuration was optimised during the design stage to suit how the space would actually be used.

Lighting and Detail Execution

Under-cabinet LED lighting was incorporated as part of the technical specification rather than added as an afterthought. This enhances both task visibility and the visual separation between wall units and splashback.

In flat-front kitchens, precision becomes critical. Consistent panel gaps, straight vertical lines, and controlled junctions between tall units and walls are essential to achieving a premium result. The cabinetry was manufactured and installed with these tolerances in mind, following the structured approach explained in how bespoke furniture really works.

Design Development and Manufacturing Process

Prior to production, the layout and proportions were confirmed through detailed visualisation and dimensional planning. This stage ensures that door splits, appliance integration, and tall unit positioning are resolved before manufacturing begins.

Our dedicated kitchen design service focuses on eliminating compromise at the installation stage by resolving structural and visual details early. Once approved, cabinetry is produced precisely to specification and delivered as a coherent, engineered set rather than assembled from pre-sized components.

Location

This kitchen was manufactured in our workshop and installed for a Wakefield, West Yorkshire client seeking a modern, low-reflective finish combined with structural durability. The result is a clean-lined, proportionally balanced kitchen that demonstrates how material selection and precise manufacturing define the final quality of a space.